Digital Foundations for Excellent Results

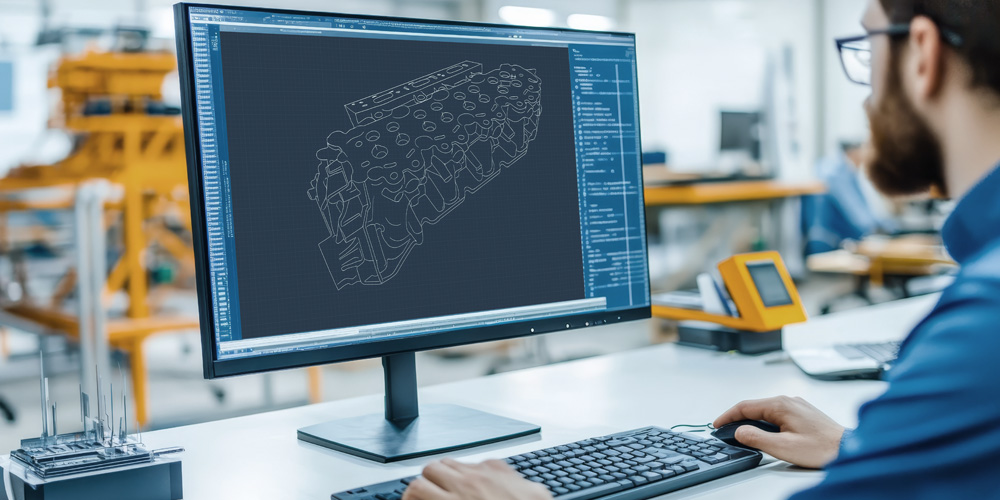

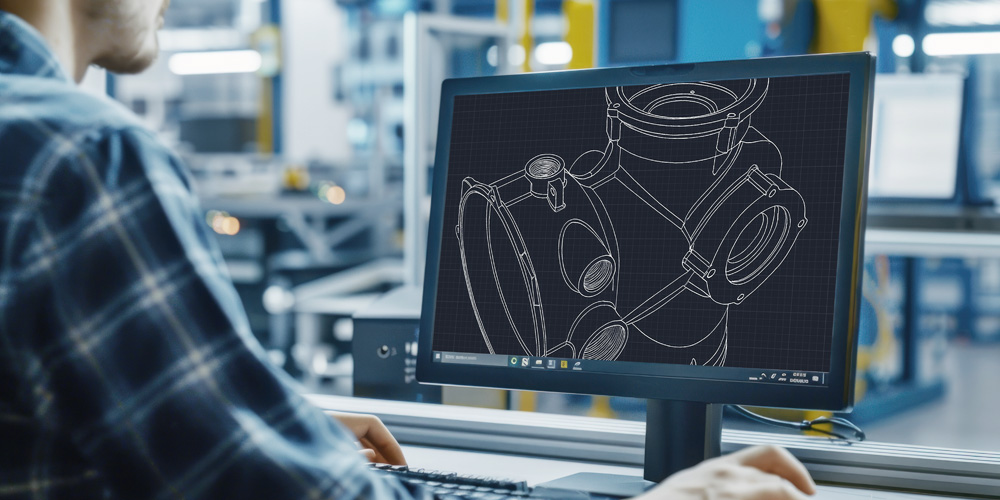

Throughout Bridge Aluminium we provide CAD and technical support as part of our aluminium casting services for a range of industries. Our team works closely with customers during the early stages of a project to ensure designs are suitable for manufacture and aligned with casting best practices. Using advanced CAD software, we help develop components that meet both functional and production requirements, with careful attention to structural integrity, dimensional accuracy, and material efficiency. Our approach integrates CAD design with simulation technology to identify potential issues before tooling begins. By modelling gating systems, material flow, and solidification, we can refine designs and reduce the risk of casting defects. This supports a smoother transition from concept to production while ensuring reliable and consistent component performance.

Shaping Aluminium Through Smarter Design

Hitting the target

Throughout the development process, CAD data plays a key role in maintaining quality and compatibility. Dimensional checks and inspection protocols are guided by the original digital models, ensuring accuracy across each stage of manufacture. Our team uses this data to manage tolerances, monitor critical dimensions, and implement robust quality control practices, all within a structured IATF-certified framework. This ensures traceability and repeatability across every batch. As a specialist aluminium foundry Group, we support multiple casting methods, including sand, gravity, low-pressure, and high-pressure techniques. The choice of process depends on the requirements of the part and is supported by CAD-based tooling design that ensures moulds and cores are developed to high standards.

Tooling layouts are guided by practical experience and simulation feedback, helping to reduce lead times and avoid costly modifications. We understand that every project is different, and our CAD support is tailored accordingly. From early feasibility assessments through to engineering release, our team remains focused on delivering practical, production-ready solutions. Whether for automotive powertrain, structural castings, or industrial components, we work with customers to understand their technical challenges and develop castings that meet performance, cost, and delivery targets.

Flexibility

Bridge Aluminium has the technical and production capacity as well as financial resources to support complex or high-volume programmes. Our Group gives us the flexibility to respond to customer needs while maintaining the attention to detail that comes from decades of foundry experience. We welcome enquiries from engineers, buyers, and project teams looking to explore the possibilities of aluminium casting through a CAD-led approach. Our technical staff are available to discuss design intent, review component demands, and assess the suitability of our casting processes for your application. All proposals are subject to project-specific review to ensure we are the right fit for your requirements. We aim to offer practical guidance and reliable outcomes, without making promises that cannot be backed by experience and evidence.

Trusted by Leading Brands