Are you Looking For

a Foundry That Uses The Coscast Process?

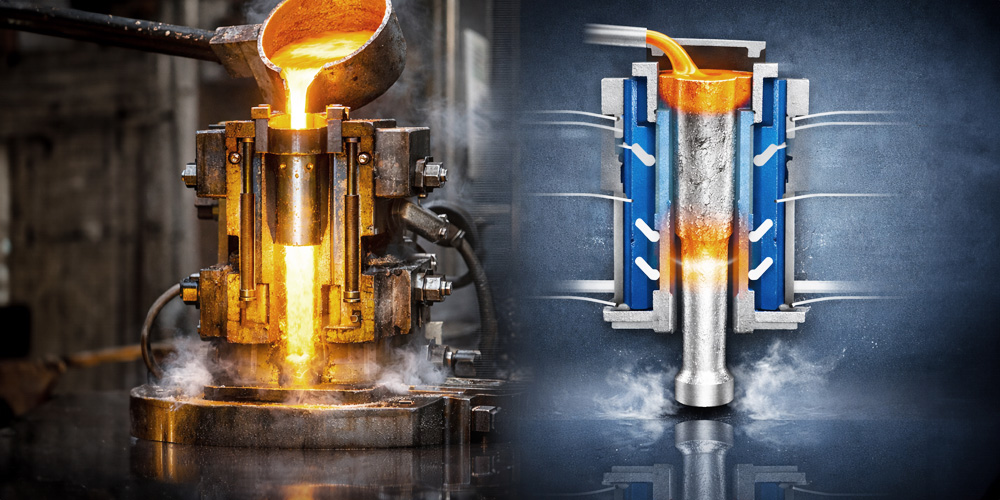

The Coscast process is a specialised aluminium casting method used to produce high-quality components with excellent strength, consistency, and reliability. It is designed to overcome some of the common issues found in traditional casting methods, such as porosity, uneven grain structure, and internal defects. At its core, Coscast focuses on controlling how molten aluminium solidifies, which has a major impact on the final performance of the casting. In the Coscast process, molten aluminium is poured into a vertical, water-cooled mould. As the metal enters the mould, it begins to cool and solidify from the outside in. What makes this process different is the way the mould behaves during solidification. The mould is gently oscillated, meaning it moves in a controlled, repetitive motion as the aluminium cools. This movement reduces friction between the solidifying metal and the mould walls, allowing the casting to form smoothly without tearing or cracking.

Finding The Right Service for You

THE COSCAST PROCESS EXPLAINED

Cooling is carefully managed throughout the process. Water flows around the mould to remove heat at a controlled rate, ensuring the aluminium solidifies evenly. This controlled cooling helps to create a fine, uniform grain structure within the metal. A consistent grain structure is important because it improves mechanical properties such as strength, fatigue resistance, and durability. It also reduces the likelihood of weak points forming within the casting. As the aluminium continues to solidify, the casting is steadily withdrawn from the mould. Because the process is continuous and tightly controlled, the metal maintains consistent quality along its entire length.

This makes Coscast particularly well suited for producing components where reliability and repeatability are critical. The finished castings typically show very low levels of porosity and excellent internal soundness compared to many conventional casting methods. Another key advantage of the Coscast process is surface quality. The controlled solidification and reduced friction within the mould result in a smoother surface finish. This can reduce the amount of machining required after casting, saving time and cost during later stages of production. Where machining is required, the consistent internal structure of Coscast material makes it more predictable and easier to machine accurately.

EFFICIENCY

The Coscast process is often used for components that must perform under high stress or demanding conditions. These include structural parts, automotive components, and applications where strength-to-weight ratio is important. Because aluminium cast using Coscast has improved mechanical properties, designers can often achieve the required performance with thinner sections, helping to reduce overall weight without compromising strength. Quality control plays a central role in the Coscast process. Temperature, cooling rates, and mould movement are all closely monitored and adjusted as needed. This level of control helps ensure repeatable results from one casting to the next.

It also allows foundries to meet tight specifications and deliver consistent performance across production runs. In simple terms, the Coscast process improves aluminium casting by controlling how the metal cools and solidifies. By reducing defects, improving grain structure, and delivering consistent quality, it produces castings that are strong, reliable, and suitable for demanding applications. The result is a process that combines efficiency with high material integrity, making it a trusted solution for manufacturers who require dependable aluminium components.

Trusted by Leading Brands