CUTTING EDGE & EFFICIENT

At Bridge Aluminium, development is at the core of our innovation strategy and long-term success. We are committed to advancing our capabilities, technologies, and expertise to meet the ever-evolving demands of modern engineering and manufacturing. Our development process is driven by collaboration, precision, and performance. We continually invest in new technologies and refine our methods to deliver high-quality aluminium casting solutions across a broad range of industries. By combining decades of experience with forward-thinking research, we ensure that our solutions remain cutting-edge, efficient, and reliable. We understand that every project brings unique challenges. That’s why our development team works closely with customers from the early design stages through to final production. This partnership-focused approach allows us to tailor our casting methods to specific project requirements, ensuring optimal results and performance. From component geometry and alloy selection to tooling design and prototyping, we bring a detailed, engineering-led mindset to every step of the process.

DEVELOPING THE FUTURE

CONSISTENT INNOVATION

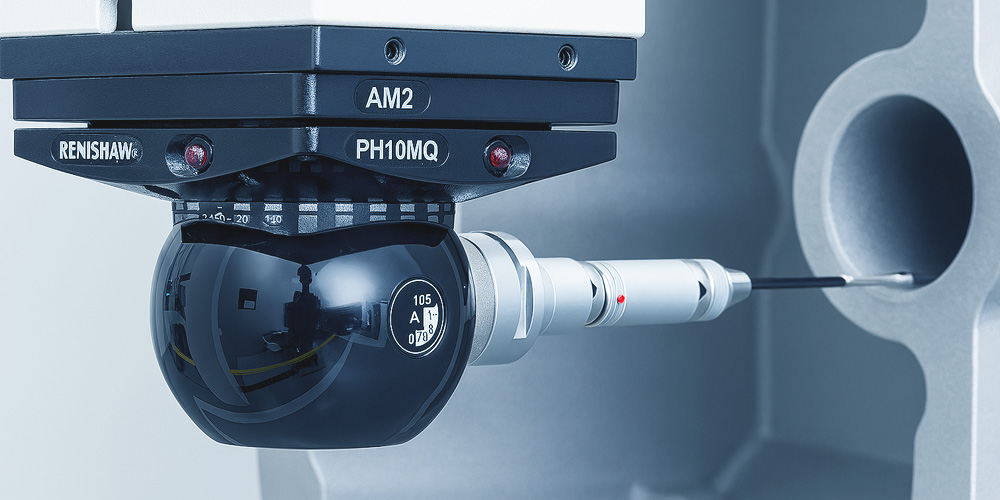

Innovation within our development team is supported by in-house capabilities that include CAD modelling, simulation software, rapid prototyping, and tooling development. These technologies enable us to refine designs quickly and efficiently, significantly reducing lead times and improving final component quality. Whether we’re supporting small-scale prototyping or large-volume production, our developmental methods ensure accuracy, consistency, and cost-effectiveness. Bridge Aluminium also benefits from being able to offer all of the mainstream aluminium casting processes, allowing us to share best practices and implement consistent improvements across our facilities.

SUPPORTING YOUR GOALS

Sustainability is another essential pillar of our development strategy. We are constantly exploring more energy-efficient processes and sustainable material practices to help reduce environmental impact. Through ongoing innovation, we aim to create components that not only meet technical performance targets but also support broader environmental and industry sustainability goals. Our development work also extends into staff training and technical progression. We believe that investing in our people is as crucial as investing in our machinery. Our engineering and technical teams undergo continuous training to keep up with the latest trends, regulatory standards, and customer expectations. At Bridge Aluminium, we don’t stand still. Our commitment to development enables us to deliver industry-leading casting solutions that stand the test of time. Whether you’re looking to optimise a new product design or improve the efficiency of an existing component, our expert team is ready to support your goals with experience, innovation, and dedication.

Trusted by Leading Brands