DESIGN FOR MANUFACTURE

At Bridge Aluminium, we understand that successful casting starts long before the metal is poured. Our specialist Design for Manufacture (DFM) services ensure that every component we produce is optimised for efficiency, quality and cost-effectiveness from the earliest stages of product development. Whether you’re looking to launch a new product or improve an existing design, our DFM process is a vital part of bringing precision-engineered components to life. Design for Manufacture is a collaborative engineering approach that ensures components are designed with manufacturing feasibility and cost in mind. It involves analysing a product’s design to identify opportunities for simplifying production, enhancing performance and reducing waste. At Bridge Aluminium, DFM plays a critical role in aligning design intent with the realities of casting processes such as high pressure, low pressure, gravity and sand casting.

Ideas bought to life

THE BENFITS

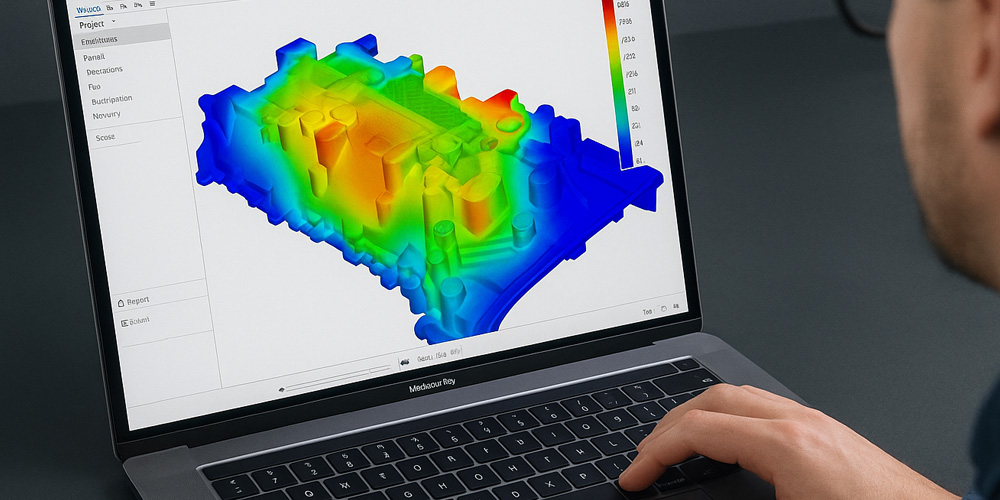

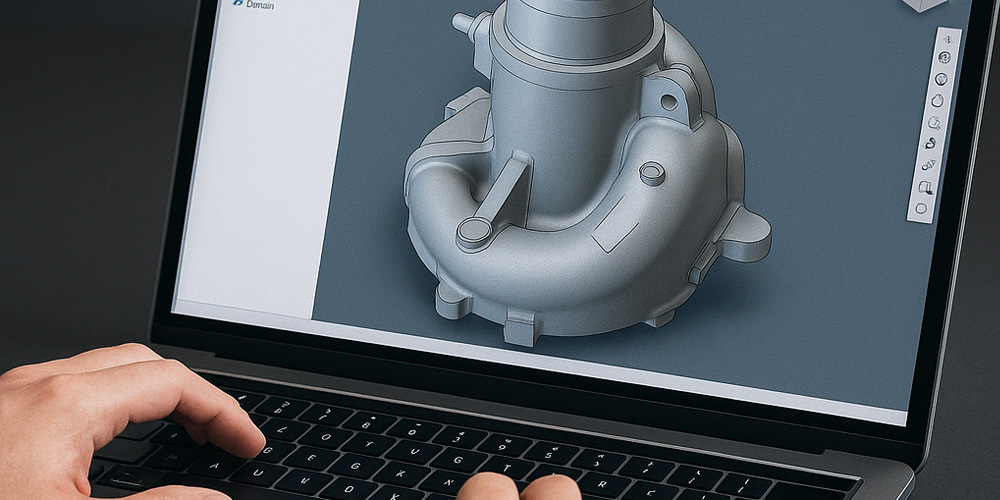

By involving our engineering team early in the development cycle, we help clients reduce lead times, minimise tooling modifications, and improve product consistency. The result is a component that not only performs reliably but is also manufactured as efficiently as possible. Our DFM approach begins with a deep understanding of your requirements. We collaborate closely with your design and engineering teams to assess functionality, geometry and material selection. Using advanced CAD systems and simulation tools, we evaluate how your component will behave during the casting process. From flow and solidification analysis to potential shrinkage or porosity issues, our team applies years of foundry knowledge to fine-tune the design before tooling begins. Once the analysis is complete, we provide actionable recommendations on how to modify designs for better castability and cost-efficiency. This may involve adjusting wall thicknesses, simplifying complex geometries, or suggesting alternative alloys. All changes are proposed with a clear focus on maintaining part performance while ensuring ease of manufacture.

WHY CHOOSE BRIDGE ALUMINIUM FOR DFM

With access to three world-class foundries across the United Kingdom, we are uniquely positioned to support complex casting challenges across sectors including automotive, off-highway, construction equipment and braking systems. Our in-house tooling design and prototyping capabilities allow us to quickly validate DFM changes and move seamlessly into full production. Bridge Aluminium offers optimised DFM services that are an integral part of our commitment to delivering high-performance components that meet the most demanding specifications. By enhancing your design for manufacture from the outset, we help you bring products to market faster, more reliably, and more economically. Get in touch with our team today to find out how our DFM expertise can add value to your next project.

Trusted by Leading Brands