A Finish Above the Rest

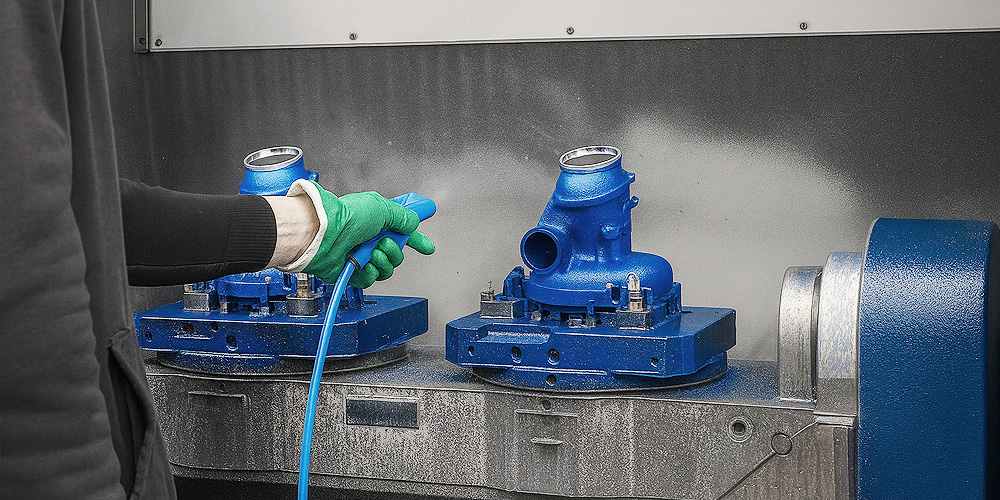

Finishes and treatments play a vital role in the work we do at Bridge Aluminium. Every component that passes through our foundry is refined with care to ensure it leaves our facility in the best possible condition. Finishing is not treated as an afterthought but as an essential stage that enhances strength, reliability and appearance. By combining precision techniques with a commitment to quality, our finishes and treatments bring out the full potential of every casting. The process begins with a strong focus on accuracy. Surfaces are carefully prepared to achieve uniformity and durability, creating castings that perform in demanding environments while maintaining their integrity. Our team applies rigorous checks at every stage, ensuring that each finish is consistent across both small and large production runs. This meticulous approach results in components that deliver long-lasting performance while meeting the highest expectations for both function and presentation.

Finishing Touches That Make the Difference

Delivering Confidence

Finishes and treatments are also about delivering confidence. Customers rely on us to provide components that not only perform effectively but also present themselves to the highest standard. Whether a project requires subtle refinement or a refined aesthetic, our treatments ensure the final product aligns with the vision and needs of our clients. Surfaces are smooth, precise and visually consistent, leaving a professional finish that reflects our pride in workmanship. Environmental responsibility is embedded in the way we approach every finish. We continually refine our processes to reduce waste, conserve resources and improve energy efficiency. By integrating sustainability into our treatments, we create results that are both effective and environmentally responsible.

This ensures that our customers benefit from components that perform well while also supporting modern expectations for sustainable manufacturing practices. A well-applied finish can elevate a component from functional to exceptional. Expertly treated surfaces not only enhance durability but also add an aesthetic value that helps products stand out. Our treatments highlight the detail and precision of our castings, ensuring that customers receive components which function flawlessly and also look the part. This careful balance of performance and visual appeal demonstrates the importance we place on every stage of production.

Finishes Designed to Impress

At Bridge Aluminium, finishes and treatments are a clear expression of our wider commitment to quality, customer service, sustainability and aesthetics. Every stage of the process is approached with the same level of dedication and precision that defines our casting work, ensuring that the end result is more than a functional component. Each item is handled with care, refined to meet the highest standards, and inspected to confirm consistency and durability. By applying this attention to detail, we not only enhance the performance and longevity of our castings but also ensure they carry an appearance that reflects professionalism and craftsmanship. Our customers can rely on us to deliver components that meet technical demands, align with sustainable practices and present themselves with a finish that inspires confidence. In doing so, we guarantee that every component leaving our facility is ready to perform, impress and last.

Trusted by Leading Brands