Defying Limits

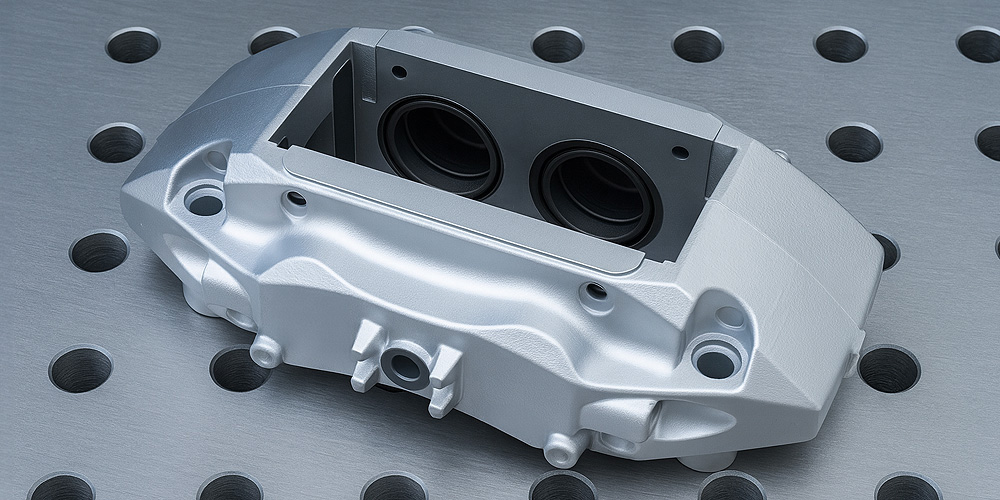

At Bridge Aluminium we have over 100 years’ experience in the production of high-quality aluminium components using the gravity die casting process. This method is widely recognised for delivering strength, accuracy, and consistency, making it an ideal solution for industries such as automotive, rotary transmission and construction equipment where reliability is essential. By combining our technical expertise with modern equipment, we are able to supply durable products that meet the exacting standards of our customers. Gravity die casting is a permanent mould casting technique in which molten aluminium is poured into a steel or iron die using gravity as the only force. Unlike pressure die casting, which injects metal at high speed and high pressure, gravity die casting relies on a steady, controlled pour. This allows the molten metal to flow smoothly into the mould cavity, reducing turbulence and leading to a cleaner and more precise casting. Once the aluminium has cooled and solidified it takes on the exact form of the die, producing a component with excellent dimensional accuracy and a strong, dense structure.

Harnessing Gravity for Stronger Aluminium Solutions

Gravity at Work

The process begins with careful preparation of the mould. Each die is preheated to a specific temperature and coated with a specialist release agent to prevent sticking and ensure a smooth finish. The molten aluminium is then poured steadily into the die, filling every detail of the cavity. As it cools, the metal solidifies into the required shape and is removed from the die before undergoing any finishing operations that may be needed, such as trimming, machining, or surface treatments. The reusable nature of the die means that this process can be repeated consistently, producing identical parts across many cycles and maintaining quality throughout the production run.

One of the key benefits of gravity die casting is the strength and durability it imparts to the finished components. The parts are denser and less porous than those produced by sand casting, which enhances their performance in demanding environments. Dimensional accuracy and repeatability are also major advantages, as the use of a permanent die ensures that every piece meets the same standard. Although the cost of producing the die is higher initially, the ability to use it many times makes gravity die casting a cost-effective choice for medium to large production runs. The process also allows for intricate designs and smooth surface finishes, often reducing the amount of secondary machining required.

The Pull of Quality

At the Wednesbury Plant, our gravity die casting services are trusted by customers who need strong and reliable aluminium components. The process is widely used to produce automotive engine and transmission parts, structural elements for construction and engineering projects, as well as housings, brackets, and a wide variety of custom-designed components. Whatever the application, our experienced team works closely with each client to ensure that the finished product performs to specification and delivers long-term value. We take pride in being a reliable partner for businesses that require precision aluminium castings. By combining many years of knowledge with advanced casting technology, we ensure that our clients receive components that are both cost-effective and manufactured to the highest quality.

Trusted by Leading Brands