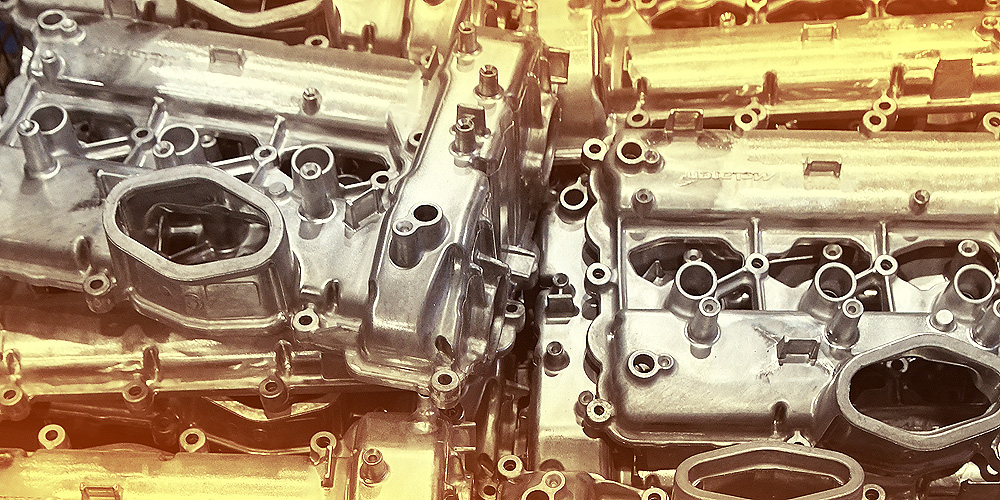

Fully Machined High Pressure Diecasting

At our Kettering Plant we specialise in delivering high quality high pressure diecasting solutions for the automotive, off-highway, and wider engineering sectors. As part of Bridge Aluminium, we bring together decades of foundry expertise with advanced manufacturing technology to create complex aluminium components that meet the highest standards of performance, reliability and dimensional accuracy. High pressure diecasting is a precision manufacturing process where molten aluminium is injected into a hardened steel die at extremely high pressure. This allows us to produce thin-walled, intricate components with excellent surface finishes and repeatable precision. The method is ideally suited for large volume production because it combines consistency with efficiency, making it one of the most cost-effective ways to manufacture robust, lightweight aluminium parts. Industries that demand strength and durability, while also seeking reductions in component weight, benefit significantly from this process.

Casting Innovation into Every Component

Delivering Strength Under High Pressure

We operate modern cold chamber diecasting machines that are specifically designed for aluminium alloys. These machines ensure accurate control over injection speed and pressure, creating castings that are strong, durable and require minimal secondary finishing. Our in-house engineers and tooling specialists design and maintain the steel dies, ensuring each project benefits from accuracy, efficiency and the flexibility to adapt to bespoke customer requirements. From prototype development to full-scale production runs, we have the capability to manage projects at every stage. By using advanced CAD simulation, we can optimise die designs, predict flow patterns and minimise potential issues before production begins, giving our customers shorter lead times and reliable outcomes. Quality control is central to everything we do.

Each casting undergoes rigorous inspection processes, including X-ray analysis and crack detection, to ensure every part meets strict performance standards. Our facilities can also provide complete machining and finishing services, equipped with state-of-the-art CNC machinery supported by jigs and fixtures that guarantee precision. This means customers receive fully finished aluminium components that are ready for assembly in demanding applications such as powertrain systems and structural vehicle elements. We work with some of the world’s leading names in the automotive and off-highway markets, supplying powertrain components, transmission housings, engine covers and structural aluminium parts. These solutions help manufacturers reduce vehicle weight, improve efficiency and meet environmental targets without compromising on durability or strength. Our expertise ensures that every component we produce performs reliably under the most challenging conditions.

Rising to the Challenge With High Pressure Diecasting

The success of the Kettering Foundry is built on technical capability, investment in technology and strong customer partnerships. By offering dedicated engineering support, in-house tooling design and comprehensive quality management, we provide a complete high pressure diecasting service that goes far beyond supplying raw castings. Whether the requirement is for a small batch of prototype parts or a high-volume production programme, we deliver components that combine precision, consistency and long-term value.

Trusted by Leading Brands