Aluminium Low Pressure Die Casting With

Less Pressure & More Possibility

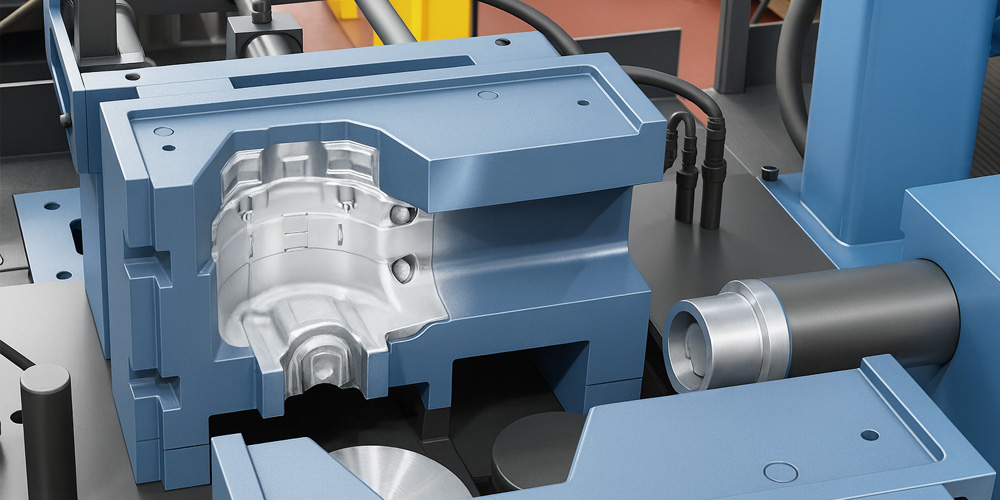

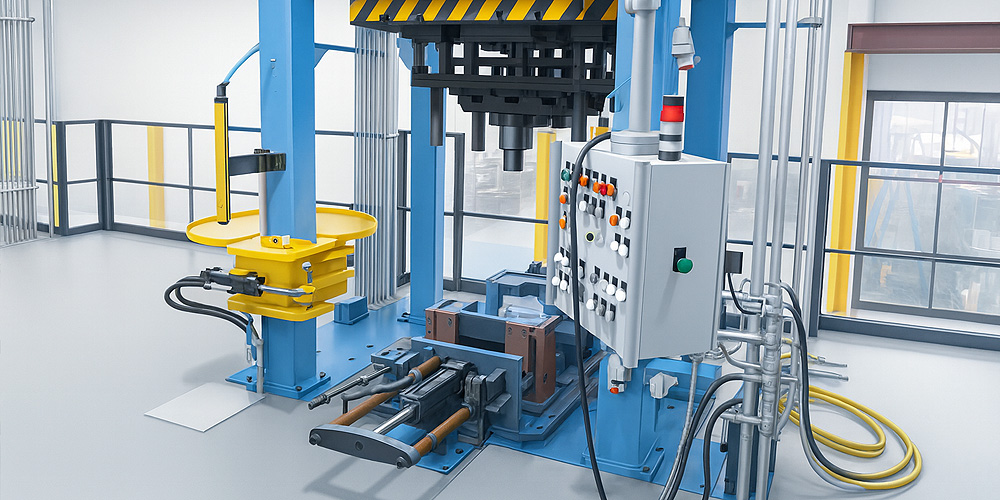

At Bridge Aluminium, we specialise in delivering high-quality aluminium components through a wide range of casting methods, including our advanced low pressure die casting process. This technique is widely recognised across the automotive, aerospace, and engineering sectors for producing strong, precise, and complex components that demand both accuracy and durability. By combining our expertise with modern foundry technology, we ensure every casting meets the highest standards of performance and reliability. Low pressure die casting is a controlled process that uses gentle air pressure to move molten aluminium from a sealed crucible into a permanent steel mould, or die. Unlike gravity die casting, where the molten metal flows naturally downward, or high pressure die casting, where it is forced at extreme pressures, this process applies a steady, low pressure of around one bar. The molten metal rises smoothly into the die cavity from the bottom upwards, reducing turbulence and minimising the risk of air pockets or porosity. Once the metal solidifies, the pressure is released and the finished component is removed, ready for any final finishing or machining.

Casting the Advantage in Aluminium

Why Low Pressure Delivers High Standards

One of the major advantages of low pressure die casting is the exceptional quality of the components it produces. Because the molten aluminium fills the mould from the base upwards, the risk of defects is significantly reduced. This results in dense, structurally sound parts with excellent mechanical properties. The method is particularly well suited for components that must perform under demanding conditions, such as braking components, suspension parts, aerospace structures, or high-performance engineering applications. The ability to use intricate sand cores within the die also allows us to create complex internal cavities and detailed shapes, giving our customers greater design freedom. At Bridge Aluminium Wednesbury and Kettering, we understand that consistency is key. Our low pressure die casting facilities are designed to deliver repeatable results across production runs, ensuring that every part meets exact specifications time after time. The process is highly efficient, with minimal waste of metal, making it an economical choice for medium to high production volumes where quality cannot be compromised. Our team of skilled technicians oversee every stage, from the careful preparation of the crucible and die through to the application of pressure and the final inspection of castings.

What Sets Us Apart with low pressure die casting

What sets us apart is not only our technical expertise but also our commitment to our customers. We do more than manufacture components; we work alongside our clients to fully understand their requirements, advising on the best casting approach to achieve the ideal balance of performance, efficiency, and cost-effectiveness. Our knowledge of low pressure die casting allows us to provide practical solutions to complex design challenges, helping our customers turn their ideas into reality. By choosing Wednesbury or Worcester for low pressure die casting, you gain a reliable partner who values precision, craftsmanship, and long-term results. Whether you need safety-critical automotive components, lightweight yet strong engine transmission parts, or custom-engineered aluminium solutions, we have the capability and experience to deliver. Our reputation is built on reliability and quality, and we take pride in producing castings that perform exactly as intended.

Trusted by Leading Brands