Setting the Standard

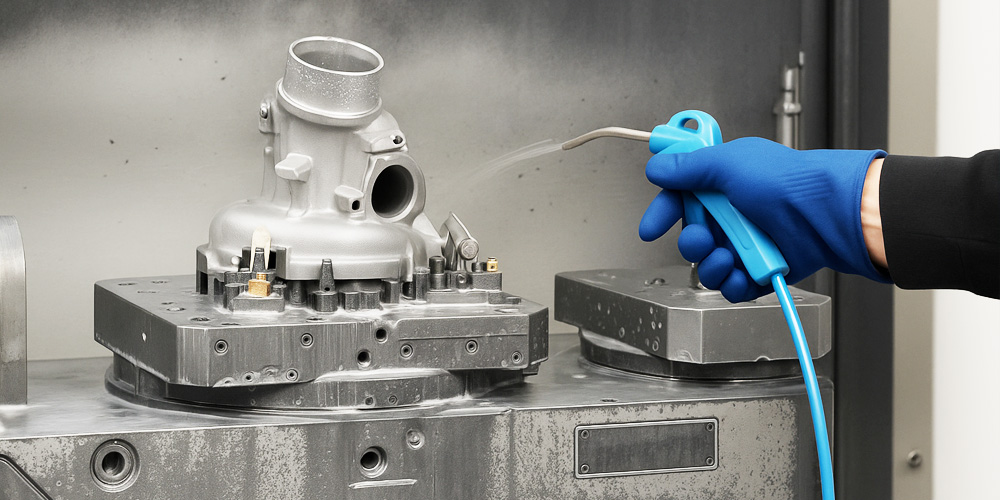

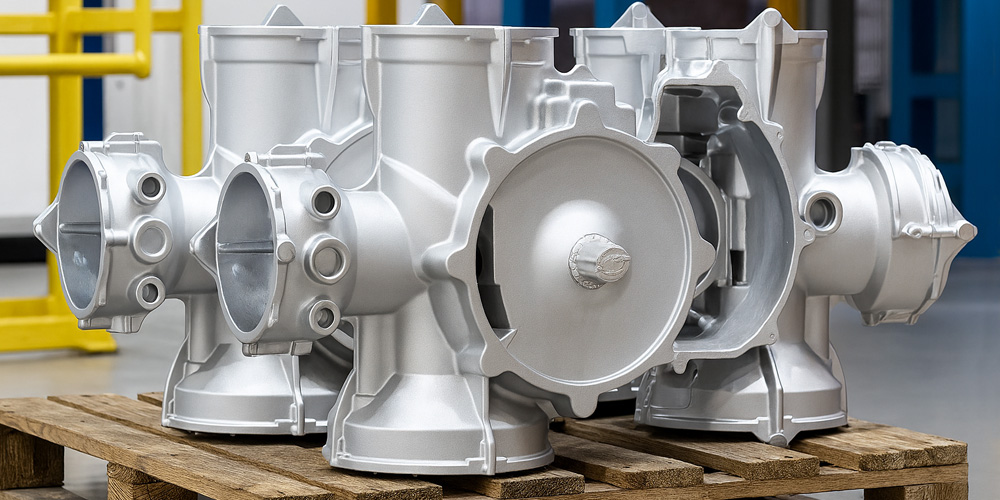

Bridge Aluminium places quality at the centre of every stage of its operations. From the initial casting design to final inspection, every component produced is subject to strict process control, comprehensive testing and continuous improvement. The company’s reputation has been built on its ability to deliver aluminium castings that meet demanding performance, safety and durability standards across the automotive, off-highway and precision engineering sectors. At the core of our quality approach is a robust framework that combines skilled craftsmanship with advanced technology. Magmasoft casting simulation software is used in the early stages of production to predict flow, solidification and cooling behaviour, reducing the likelihood of defects and improving consistency. This preventative focus is matched by an equally rigorous inspection regime, which includes X-ray testing, dye penetrant methods and crack detection systems all conforming to IATF approval.

Excellence Through Control and Compliance

Engineered for Precision

Each casting is manufactured with traceability and compliance in mind. Every process is documented and monitored to ensure alignment with customer specifications and industry regulations. The quality team works closely with production, engineering and supply chain departments to ensure that standards are upheld from raw material sourcing to final dispatch. Internal audits, supplier assessments and process reviews form part of a wider commitment to operational transparency and continual development.

All three foundries are designed to support high-integrity manufacturing. The environment is controlled, well-maintained and equipped with dedicated areas for inspection, machining and finishing. Thermal treatment processes are carried out in-house, allowing for greater control over material properties such as strength, hardness and durability. Dedicated production cells are managed by experienced operators who work to defined tolerances, ensuring each component meets the exact requirements set by the customer.

Building Quality from the Inside Out

People are a key component of maintaining our quality system. Staff across all departments are trained in quality awareness, process adherence and inspection techniques. From foundry operatives to quality engineers, the workforce understands the importance of consistency and attention to detail. Quality objectives are communicated clearly, with progress reviewed regularly to maintain high performance.

By investing in modern equipment, digital tools and employee development, Bridge Aluminium continues to enhance its ability to deliver castings that perform reliably under real-world conditions. The company’s approach to quality is not limited to end-product inspection but is embedded into every layer of production. This ensures that customers receive components that are not only fit for purpose but manufactured with a clear focus on integrity, precision and long-term performance.

Trusted by Leading Brands