Off Highway

The off-highway sector demands equipment that can handle punishing conditions, extreme loads, and long operational hours. At Bridge Aluminium, we specialise in delivering castings that provide the durability, reliability, and precision required for vehicles and machinery used in construction, mining, and agriculture. Our castings are designed to perform flawlessly in environments where downtime is costly and reliability is non-negotiable. By combining sand, gravity, low pressure, and high pressure die casting techniques, we manufacture components that balance strength with lightweight efficiency, helping to reduce overall vehicle weight without compromising performance. Every part undergoes rigorous inspection, including in-house x-ray and crack detection, to ensure it meets the highest safety and quality standards. Our three foundries – Wednesbury, Kettering & Worcester – give us the capacity to serve customers with both high-volume production and specialist components.

Oil & Gas

The oil and gas industry operates in some of the most demanding environments on earth, requiring components that can withstand high pressures, corrosive substances, and extreme temperatures. We are ideally placed to meet these challenges with precision-engineered aluminium castings that deliver exceptional performance and durability. From subsea equipment to onshore and offshore applications, our castings are manufactured to the tightest tolerances, ensuring the integrity of critical systems where failure is not an option. With advanced foundry capabilities across our three sites, we can produce complex geometries with outstanding consistency, supported by rigorous non-destructive testing to guarantee safety and reliability. Our logistics network ensures we can meet tight deadlines and deliver globally, providing confidence that projects stay on track. Sustainability is also central to our approach, and we continually work to reduce the carbon footprint of our production and delivery processes. For oil and gas operators, Bridge Aluminium offers the perfect combination of technical expertise, robust quality control, and dependable global supply.

Wind Turbines

As the world shifts towards renewable energy, the wind turbine sector requires suppliers that can deliver precision, reliability, and sustainability. We support this growing industry with advanced aluminium castings that meet the structural and performance demands of turbine systems. Our expertise in complex aluminium geometries enables us to produce components that are both lightweight and extremely durable, improving efficiency while ensuring long-term reliability. With operations at Wednesbury, Kettering and Worcester, we can scale production to match the rapid growth of renewable energy projects. Every casting is subjected to stringent testing, including x-ray and crack detection, to ensure flawless quality in critical components. Beyond manufacturing, our logistics capability ensures timely delivery to renewable projects worldwide, helping to keep installation schedules on track. We also share the sector’s commitment to sustainability, embedding eco-friendly practices across our operations. By combining technical excellence with reliable, efficient logistics, Bridge Aluminium positions itself as a trusted partner in powering the global transition to cleaner energy. For aluminium castings for wind turbines and more, look no further than Bridge Aluminium.

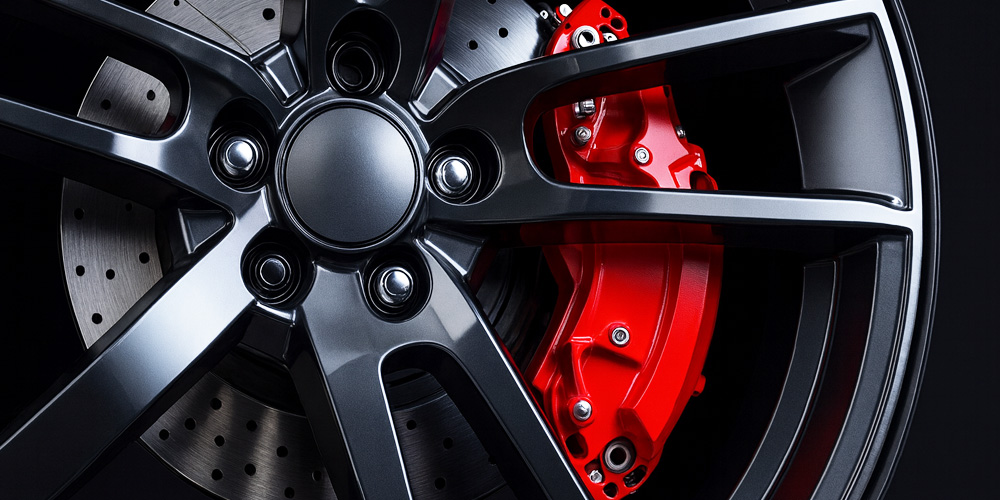

Braking

Safety is at the heart of braking systems, and manufacturers require castings that deliver consistent, fault-free performance under high stress. We have a proven track record of providing the precision and reliability that this sector demands, producing castings to exact tolerances that guarantee dependable operation in safety-critical environments. Using advanced gravity, low pressure, and sand casting methods, we are able to create components that combine strength, accuracy, and lightweight design. To ensure the highest quality, we integrate non-destructive testing into our production process, including in-house x-ray and crack detection, so defects are identified and eliminated before components leave our facilities. Our foundries in Wednesbury, Kettering and Worcester offer both the capacity and flexibility to supply high volumes while maintaining rigorous quality standards. Beyond manufacturing, our logistics network provides on-time delivery across the UK and international markets, giving customers confidence that supply chains remain uninterrupted. With a focus on precision, reliability, and efficiency, Bridge Aluminium is the perfect partner for braking system manufacturers worldwide.

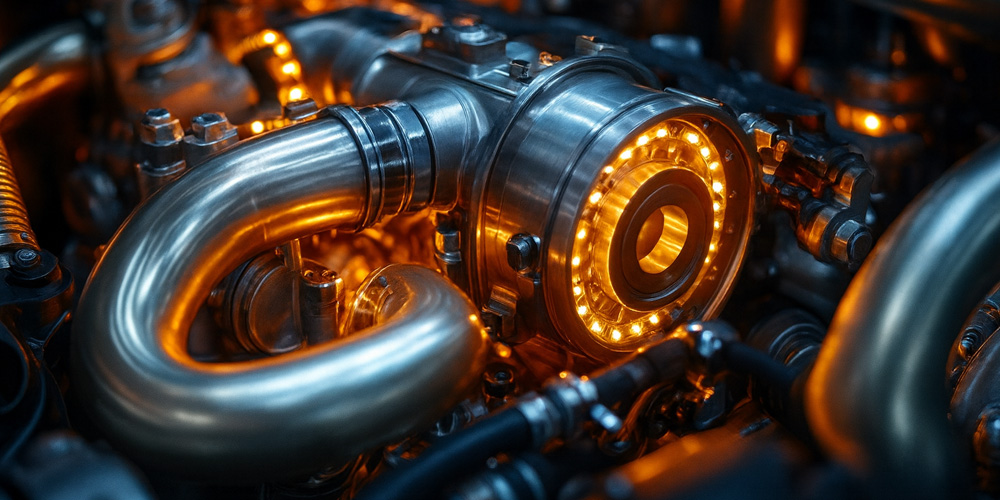

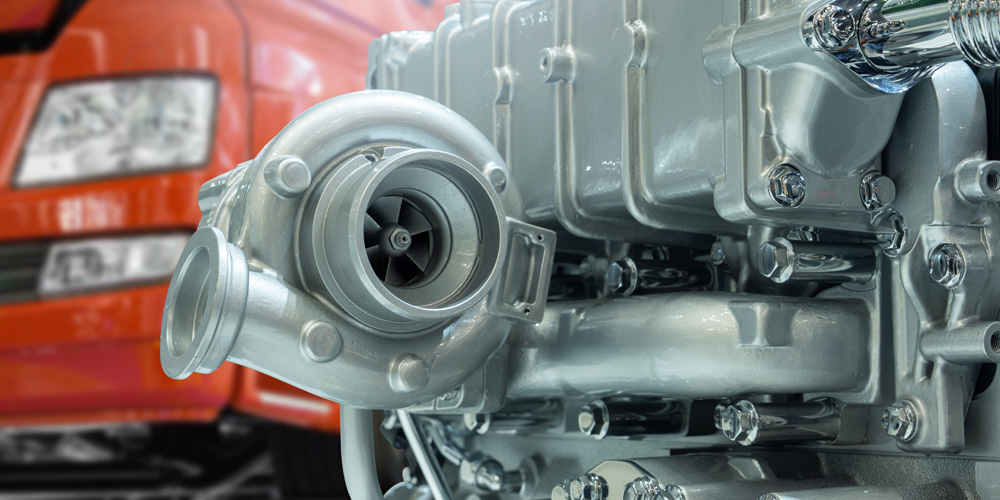

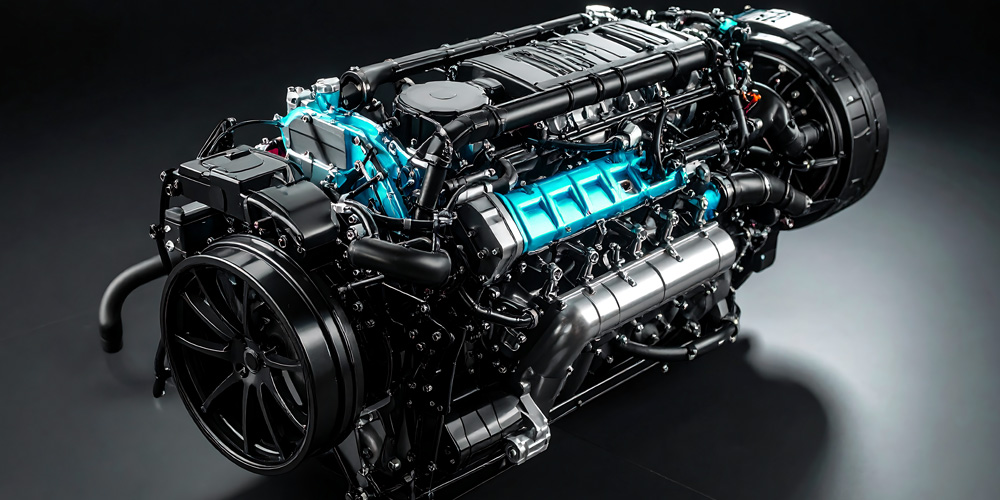

Turbo Chargers

Turbochargers require castings that are lightweight, thermally efficient, and capable of withstanding extreme stresses. Bridge Aluminium provides the technical expertise, manufacturing excellence and many years of experience needed to meet these challenges, producing components that enhance engine performance and reliability. By employing advanced casting technologies, supported by machining and finishing capabilities, we deliver parts that meet the exact specifications of leading turbocharger manufacturers. Our in-house testing processes, including x-ray and crack detection, guarantee the integrity of every component, ensuring flawless performance in demanding applications. With foundries based in Wednesbury, Kettering and Worcester, we have the capacity to support both high-volume production and specialised projects, all backed by a logistics network that ensures fast, reliable global delivery. In addition, our commitment to sustainability means our production processes are continually optimised to reduce waste and energy consumption, aligning with the environmental goals of many of our customers.

Auto Sport

In the fast-paced world of Autosport, performance, precision, and reliability are non-negotiable. Bridge Aluminium delivers high-quality castings that meet the stringent requirements of motorsport manufacturers, where lightweight strength and flawless accuracy can mean the difference between winning and losing. Our foundries at Wednesbury, Kettering and Worcester are equipped with the latest casting technologies, allowing us to create complex parts that meet exact performance specifications. Every casting is rigorously inspected with advanced non-destructive testing techniques to ensure the integrity and consistency needed for high-performance applications. What sets us apart is our agility—our logistics network and flexible production capacity allow us to respond rapidly to urgent demands and tight schedules, ensuring teams get the components they need without delay. With sustainability increasingly important to the sector, we also focus on reducing environmental impact across our operations. By combining speed, innovation, and precision, Bridge Aluminium is the perfect partner for Autosport manufacturers competing at the highest level.

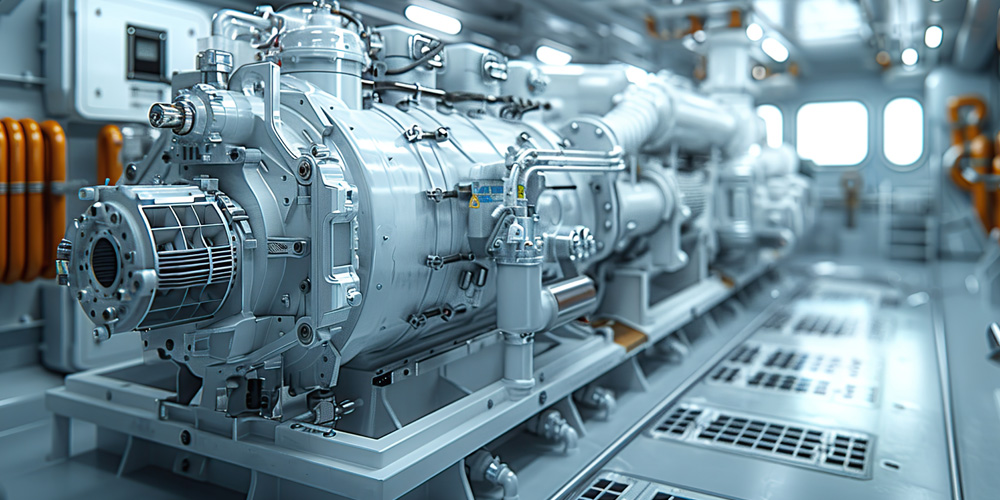

Marine

Marine applications demand components that can withstand some of the toughest operating conditions in the world, from constant exposure to saltwater to the stresses of heavy-duty operation. At Bridge Aluminium, we manufacture corrosion-resistant, durable aluminium castings designed for long-term performance in marine environments. Our three foundries — Wednesbury, Kettering and Worcester — are capable of producing both large-scale components and specialist parts, with the flexibility to adapt to the unique needs of shipbuilders and marine equipment manufacturers. Each component is subjected to rigorous testing, including in-house x-ray and crack detection, to guarantee integrity and reliability. Our logistics expertise ensures timely global delivery, enabling customers to receive high-quality castings when and where they are needed. We also embed sustainable practices into our operations, reducing the environmental footprint of both manufacturing and delivery. By combining strength, precision, and logistics excellence, Bridge Aluminium provides the marine sector with castings that meet the highest standards for safety, durability, and efficiency on the water.

Engineering excellence for global markets

Trusted by Leading Brands