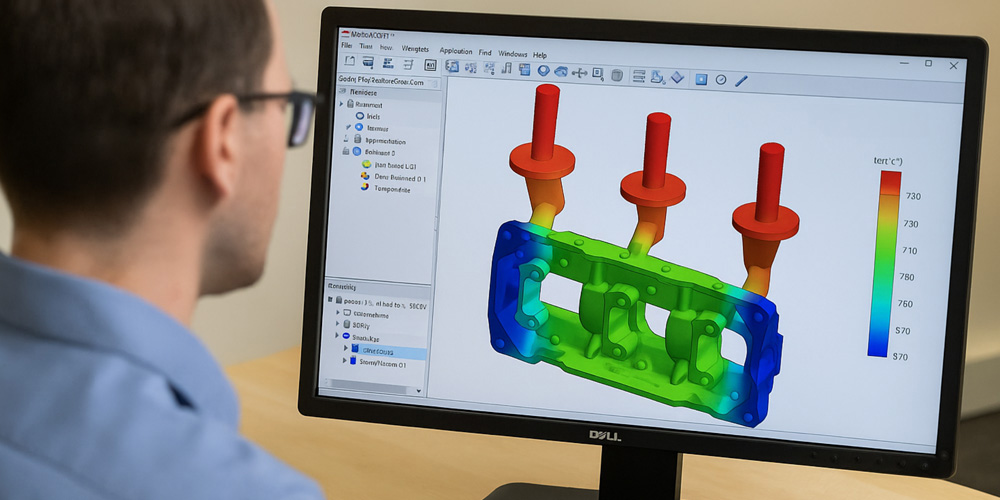

The Benefits Of Simulation Software

At Bridge Aluminium, we are always seeking ways to innovate and enhance the services we deliver to our clients. One of the most powerful tools we use to achieve this is simulation software, a cutting-edge casting simulation software that transforms the way aluminium components are designed and manufactured. Simulation software enables us to create virtual simulations of the casting process before production begins. By replicating every stage — from mould filling and solidification to cooling and potential defect formation — the software gives us an invaluable insight into how a component will behave during manufacture. This predictive capability allows us to optimise designs, refine processes, and ensure we deliver the highest levels of quality and consistency.

One of the greatest benefits of simulation software is defect prevention. Traditionally, imperfections such as porosity or shrinkage could remain hidden until after casting, often resulting in wasted materials and costly rework. With simulation software, we can identify these issues at the design stage and make the necessary adjustments before production starts. This proactive approach saves time, reduces waste, and guarantees stronger, more reliable aluminium products. Efficiency is another key advantage. By virtually testing and optimising casting designs, we reduce the need for trial-and-error on the factory floor. This streamlines our operations, shortens lead times, and ensures projects remain on schedule.

For our customers, this translates into faster delivery without any compromise on quality. Sustainability is also at the heart of what we do, and simulation software plays a vital role in helping us achieve greener outcomes. By lowering scrap rates, reducing energy use, and minimising the consumption of raw materials, the software supports our commitment to responsible manufacturing. Every improvement we make not only benefits our clients but also contributes positively to the wider environment. At Bridge Aluminium, investing in advanced tools like simulation software reflects our ongoing commitment to innovation, excellence, and sustainability. It ensures we remain at the forefront of aluminium solutions while providing our customers with products they can trust. We are proud to harness the power of simulation software to deliver consistent results and look forward to continuing to lead the way in precision aluminium manufacturing.