Improving Outcomes & Reducing Risk

With Casting Simulation Software

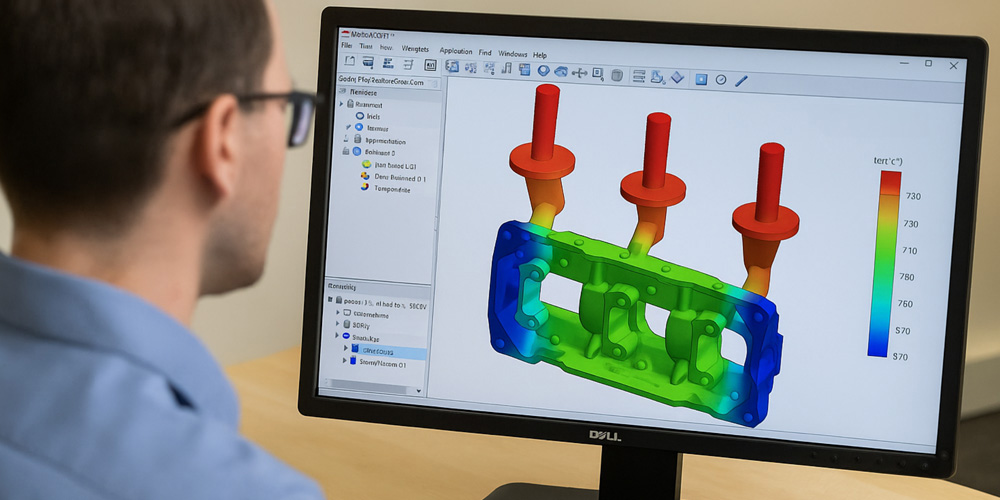

We utilise the latest simulation tools that enables foundries to digitally design, test, and refine their components before they reach the production stage. At Bridge Aluminium, we incorporate simulation software into our engineering workflows to enhance quality, consistency, and efficiency across all casting methods. By using simulation technology, at the earliest stages of development, we are able to improve outcomes and reduce the risk of costly design flaws or process instability. One of the most significant advantages of simulation software is the ability to model the entire casting process in a virtual environment. This includes mould filling, solidification, thermal gradients, and the prediction of potential defects such as shrinkage, porosity, or misruns. Through this approach, our engineers can analyse how molten aluminium behaves within a mould, which allows us to make informed decisions about gating, riser placement, and overall part geometry. This reduces reliance on physical trials and helps us deliver superior results on the first production run.

Combining Expertise with Precision

Valuable Insight

The use of simulation tools are fully integrated into our design-for-manufacture process. Our CAD and simulation teams work closely to ensure that each component is optimised not only for performance but also for process reliability. Whether we’re using gravity die casting, low-pressure casting, high pressure casting or sand casting methods, simulation software provides valuable insight into how each casting will behave under real-world conditions. This is particularly useful when developing complex or highly stressed components, such as those used in automotive powertrain assemblies. Simulation results also support process stability and repeatability, both of which are crucial when supplying components to sectors with stringent quality requirements.

By simulating different manufacturing scenarios, we can evaluate how variables such as pouring temperature, cooling rate, or alloy choice impact the final part. This enables us to define robust process windows and reduce variation, which is key to achieving high Cpk values and consistent dimensional accuracy across production batches. Another important benefit is the positive impact simulation software has on efficiency and sustainability. By optimising designs before tooling and production begin, we reduce the likelihood of scrap, rework, or late-stage modifications. This helps conserve materials, save energy, and reduce lead times—all while maintaining the high quality standards expected by our customers. It also allows us to respond more quickly to design changes or production challenges without significant disruption

Casting Simulation Software – A Core Element

Early defect detection plays an essential role in our prototyping capabilities as well. It gives customers the opportunity to review simulated performance data and validate design intent before investing in tooling. This improves confidence in the development process and supports faster decision-making, especially when working to tight deadlines or complex specifications. At Bridge Aluminium, casting simulation software is a core element of our engineering capability. It enables us to combine technical expertise with digital precision, delivering components that meet both functional requirements and production demands. By using simulation-led development, we continue to enhance the quality and reliability of our aluminium castings while supporting the evolving needs of our customers.

Trusted by Leading Brands