Ensuring Efficiency & Excellence

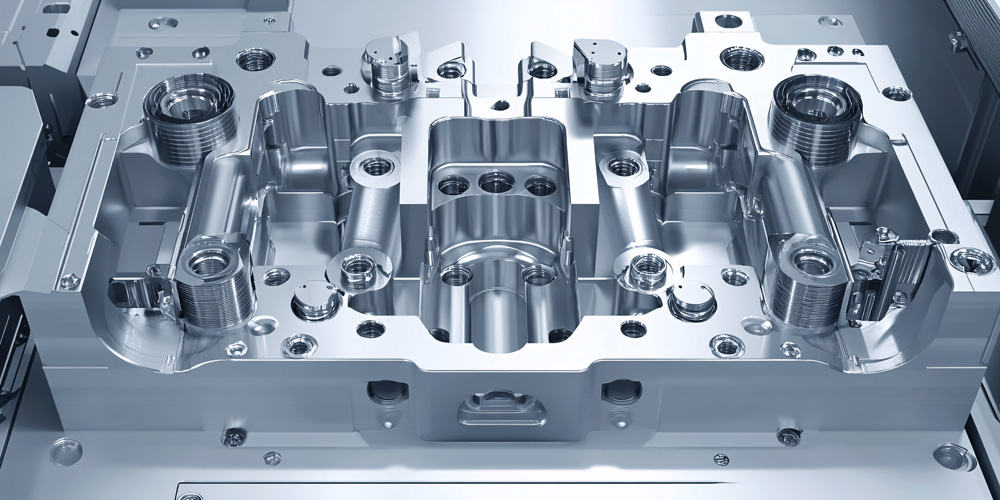

At Bridge Aluminium, precision tooling plays a vital role in the quality of every component we deliver. The performance and reliability of a cast part depend heavily on the accuracy of the tools used to create it. By investing in advanced tooling solutions, we ensure that every product meets the highest standards of accuracy, consistency and durability. Our tooling capabilities allow us to produce complex, high-performance aluminium components for demanding sectors such as automotive, off-highway and industrial applications. From prototype tools through to production-ready systems, we support customers at every stage of the process, tailoring each tool to exact requirements. Effective tooling begins with design. Our engineering team uses advanced CAD and simulation software to model and refine each tool before manufacture. This approach allows us to optimise performance, anticipate potential issues and shorten lead times. By simulating casting processes and tooling conditions, we can make adjustments at the design stage, reducing waste and ensuring efficiency once production begins.

Bridging Innovation with Precision Tooling

Consistent Results

Once a tool design has been finalised, it is manufactured using state-of-the-art machining equipment. From high-precision CNC milling to advanced cutting and grinding, we achieve the tight tolerances required for today’s complex components. Each tool is built to deliver long-term performance, capable of withstanding repeated use while maintaining dimensional accuracy. This focus on precision extends the life of the tool and ensures repeatable, consistent results. Many of our customers require castings with intricate geometries, thin walls or challenging performance criteria.

High-quality tooling is essential for delivering these outcomes. We specialise in sourcing tools that enable efficient casting of such parts, helping manufacturers reduce weight without compromising structural integrity. With expertise in both prototype and full-scale production tools, we provide complete solutions for businesses developing new products or expanding existing production lines. Every tool undergoes rigorous inspection and testing. Alongside traditional measurement methods, we employ advanced technologies such as 3D verification and non-destructive evaluation to confirm accuracy and reliability. These stringent checks give our customers confidence that the tooling will consistently deliver the required results.

Confidence

Our tooling services are built on collaboration. By working closely with customers, we gain a clear understanding of their requirements and offer guidance on design, process optimisation and cost-efficiency. This partnership approach ensures that our tooling solutions contribute directly to improved performance and productivity. Reliable tooling is fundamental to efficient manufacturing. At Bridge Aluminium, we combine advanced design, high-precision machining and robust quality control to deliver tooling solutions that add real value. Whether for new product development or ongoing production, our tools are engineered to the highest industry standards. With decades of expertise and a commitment to innovation, we continue to provide tooling solutions that give our customers confidence in their processes and competitiveness in global markets.

Trusted by Leading Brands